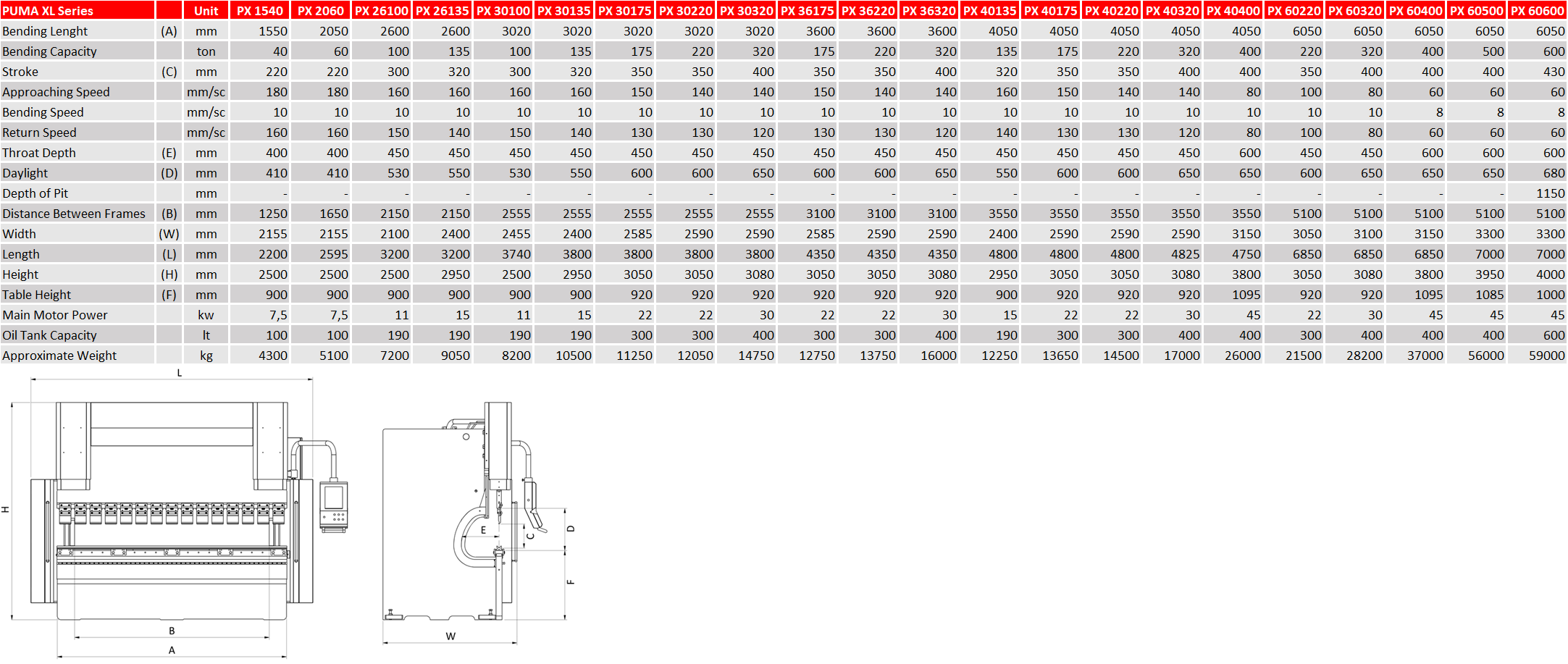

PUMA XL SERIES

DENER PUMA XL CNC

DENER PUMA XL CNC Press Brakes are born with the goal to be flexible, reliable, and advanced bending machines; Dener utilizes the most stringent manufacturing technologies during production to manufacture the highest quality machines. Based on proven design, Dener has increased working speeds, stroke, daylight, and pressing capacities of Puma XL machines.

DENER PUMA XL is a synchronized hydraulic press brake with a 2DGrahical CNC controller and offers simple operation, quick and easy 2D or numerical part programming easy setup of the machine, and auto calculation of the bend sequence. 2D offline programming feature with S 560 PC Controller gives the possibility to end users to complete bending program on an Office PC and transfer to machine by LAN or USB. These functions make Dener PUMA XL CNC Hydraulic Press Brakes very popular in sheet metal industries.

CNC CONTROLLERS

Cybelec ModEva 15T - Touchscreen 15"

DENER BACK GAUGE SYSTEM

Gauging is a main concern for press brake operators. Whether you require complex part multi station bending or single bending or production of taper bends Puma XL offers solution with 6 different back gauge options to its customer. Depending on the geometry of the parts and their complexity, all back gauge models are particularly manufactured to reach high precision and high speeds. The models which we offer to our customers are;

- Standard Puma XL back gaug

- X - R type back gauge (standard ) Ball Screw for X axis, double linear guide for X axis. 650 mm X axis stroke, 160 mm R axis stroke 2 Pcs back gauge finger manual lateral movement on linear guides Positioning accuracy: +0,03 mm Repeat accuracy: +0,03 AC servo motors for X and R axis Optional back gauge axis -X-X'-R TYPE BACK GAUGE (tilting from finger)

- X1 X2 R TYPE BACK GAUGE ( Tilting from the bar)

- X-R-Z1-Z2 TYPE BACK GAUGE (Individual Finger movement from CNC)

- X-X'-R-Z1-Z2 TYPE BACK GAUGE (Individual Finger movement from CNC and X movement from finger + 100 mm)

- X1 X2 R Z1 Z2 TYPE BACK GAUGE ( Tilting from the bar and individual finger movement)

- ATF Type 6 axis back gauge X1 X2 R1 R2 Z1 Z2 independent finger movements.

|

|

|

|

|

X1-X2-R Type Back Gauge

|

X-R-Z1-Z2 Type Back Gauge

|

X1-X2-R-Z1-Z2 Type Back Gauge

|

ATF Type 6 Axis Back Gauge

|

STROKE, DAYLIGHT & THROAT

Operators can easily use higher punches and dies and have enough stroke and daylight to manipulate the sheet metal easily. Higher punch lets operators bend deep boxes and higher V gives the possibility to bend negative edges.

Deep Throat is always a big advantage for press brake operators. To use the full bending length without any collision with side frames Dener design Puma XL machines with a deep throat. Operators can bend up to 30 degrees and depend on the model’s 450 mm deep parts without any collision in full bending length. Dener offers special throat depths as an option.

Zpět